So one of my buddies a while back asked if I would help him make an oil bag for his CB750. He showed up today and didn't have the material that would suit the situation exactly (i.e. not 18 gauge, but 1/8 plate)

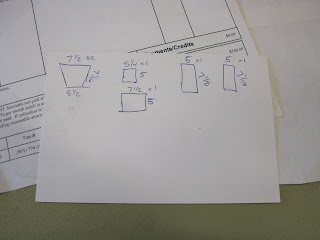

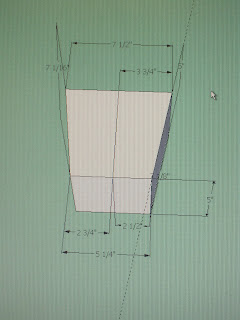

To make things better, my Solidworks licence was expired, so I had to figure out how to use Google Sketch Up. It was helpful for use to see if we still had the right volume for the bag.

Burn Baby Burn!

Like I said...not the material that would of been best. But this thickness might play into an even better idea Brady has for it later.

If you notice in the picture above I had to fill the massive gap of the century. So judge my weld accordingly...oh who am I kidding I suck ;) all GTAW btw.

I gave Dave the task to buff it up a little. I think this will turn out good. So next time we need to cut holes for the bungs, and then pressure test it.

Dave also had me take a look at his pipes. They had holes everywhere. This could of been done OK at home by him in the first place, had he remembered to chip his slag off from his FCAW wire. Kids please always chip your slag if you are going to weld over welds!!!!! So we went and polished a turd to stop some of the leaks. It will last for a while then most likely will crack under heat and pressure. Then we will redo them, and do them right. All in all though a pretty sick design, 4 to 1.

No comments:

Post a Comment